Article Plan: True Temperature Control Manual

This manual details comprehensive troubleshooting for True refrigeration, covering mechanical & electronic systems, common issues, and specific model guidance (like the T49).

It includes defrost system analysis, sensor diagnostics, refrigerant concerns, and safety precautions, alongside resources for professional support and field troubleshooting.

Maintaining precise temperature control is paramount for food safety and preservation within True refrigerators and freezers. This section introduces the core principles governing temperature regulation in these units, emphasizing the critical interplay between components like thermostats, sensors, and controllers.

True’s refrigeration systems, whether utilizing mechanical or electronic controls, are designed for consistent performance. However, fluctuations can occur due to various factors. Understanding these systems, as detailed in True Manufacturing’s resources, is vital for effective troubleshooting. This manual provides a structured approach to diagnosing and resolving temperature-related issues, ensuring optimal operation and minimizing downtime.

Understanding Temperature Control Systems in True Refrigerators

True refrigerators employ sophisticated systems to maintain stable internal temperatures. These systems rely on a closed-loop process, continuously monitoring and adjusting cooling output based on sensed conditions. Key to this is the temperature controller, which interprets sensor data and activates the compressor or defrost cycle.

The efficiency of these systems is affected by factors like door openings, product load, and ambient temperature. True’s documentation highlights the importance of proper airflow around evaporator coils. Understanding these interactions is crucial for diagnosing issues, as evidenced by discussions on platforms like Reddit regarding defrost cycles and sensor accuracy.

Mechanical vs. Electronic Control Systems

True refrigerators historically utilized mechanical temperature controls, employing thermostats with capillary bulbs to directly cycle the compressor. These systems are robust but offer limited precision and adjustment capabilities. Modern True units increasingly incorporate electronic controls, utilizing sensors and microprocessors for more accurate temperature management.

Electronic systems allow for digital displays, remote monitoring, and advanced features like temperature alarms. However, they are more susceptible to component failure. True Manufacturing advises against modifying electronic controls, suggesting professional assistance for calibration or adjustments, as noted in their documentation.

Key Components: Thermostats, Sensors, and Controllers

True refrigeration relies on a network of components for precise temperature regulation. Thermostats, in mechanical systems, physically open and close circuits; Sensors, like thermistors, provide electronic temperature readings to controllers. Controllers, often LAE models in newer True freezers, interpret sensor data and manage compressor cycles and defrost functions.

The Grasslin defrost timer, specific to freezer units, initiates defrost cycles based on time intervals. Accurate sensor readings are crucial; faulty sensors can lead to incorrect temperature control, as highlighted in Reddit discussions regarding True freezer issues.

Common Temperature Control Issues

True refrigerators can experience several temperature control problems. Fluctuating temperatures are frequent, often signaled by inconsistent cooling and potentially a rise in cabinet temperature. Ice buildup on evaporator coils, as noted in PartsFPS documentation, restricts airflow and impacts cooling efficiency, sometimes creating a ticking sound.

Underlying causes include bad sensors, controller malfunctions, low refrigerant levels, or a clogged capillary tube. These issues can disrupt the defrost cycle, leading to warmer temperatures and requiring careful diagnosis and repair.

Fluctuating Temperatures

Fluctuating temperatures within a True refrigerator indicate a control system malfunction. These variations can stem from several sources, including a failing thermostat or inaccurate sensor readings, as highlighted in Reddit discussions. Low refrigerant or a clogged capillary tube also contribute, hindering consistent cooling.

Ice buildup on the evaporator coils, restricting airflow, is a common culprit. A malfunctioning defrost system, particularly with issues in the Grasslin timer (freezer units), exacerbates this. Accurate diagnosis is crucial for restoring stable temperatures.

Inconsistent Cooling

Inconsistent cooling in True refrigerators often points to airflow restrictions or component failures. Damaged or crushed evaporator coil fins, as noted by PartsFPS, impede heat exchange. Ice buildup on these coils is a frequent cause, creating a barrier and reducing efficiency.

Refrigerant issues, such as leaks or blockages in the capillary tube, severely impact cooling performance. A malfunctioning defrost system, failing to remove ice, also contributes. Proper diagnosis requires checking both mechanical and electronic control elements.

Diagnosing Temperature Problems: Initial Checks

Begin by verifying the power supply and connections to the True refrigerator, ensuring stable operation. A thorough visual inspection of both the evaporator and condenser coils is crucial, looking for damage or obstructions. Listen for unusual noises, like a constant ticking, potentially indicating ice buildup.

Check controller settings and calibration, as incorrect configurations can cause temperature fluctuations. If issues persist, consulting True Manufacturing or a qualified technician is recommended, as Reddit users advise.

Checking Power Supply and Connections

Start with a visual inspection of the power cord and plug, ensuring no damage is present. Verify the outlet is functioning correctly using another device. Check the circuit breaker or fuse dedicated to the True refrigerator, resetting if necessary.

Inspect all internal wiring connections, looking for loose or corroded terminals. Confirm proper voltage is reaching the unit, referencing the manufacturer’s specifications. A stable power supply is fundamental for accurate temperature control.

Visual Inspection of Coils (Evaporator & Condenser)

Begin by carefully examining the condenser coils, typically located at the rear or bottom of the unit. Look for dirt, dust, or debris accumulation that restricts airflow. Next, inspect the evaporator coils inside the freezer compartment for ice buildup or physical damage.

Pay close attention to fin condition; crushed or bent fins impede heat transfer. Ensure coils are free of obstructions and that airflow isn’t compromised. Regular cleaning and fin straightening are crucial for optimal performance.

Evaporator Coil Issues & Troubleshooting

Evaporator coil problems significantly impact cooling efficiency. Excessive ice buildup, indicated by a ticking sound or rising temperatures, is a common issue. Inspect for restricted airflow due to debris or blocked vents. Check for damaged or crushed fins hindering heat exchange.

Troubleshooting involves verifying the defrost system’s operation. A malfunctioning defrost cycle leads to ice accumulation. Ensure proper sensor function and controller settings. Address any refrigerant concerns as low levels exacerbate coil issues.

Ice Buildup on Evaporator Coils: Causes and Solutions

Ice accumulation on evaporator coils drastically reduces cooling capacity. Common causes include a faulty defrost system, malfunctioning defrost timer (Grasslin in freezer units), or bad sensors misreporting temperature. Low refrigerant and clogged capillary tubes also contribute to icing.

Solutions involve verifying the defrost cycle’s functionality. Straighten damaged fins to improve airflow. Inspect and replace faulty components like the defrost heater or timer. Address refrigerant levels and capillary tube blockages for optimal performance.

Identifying Damaged or Crushed Fins

Evaporator and condenser coil fins are crucial for efficient heat transfer. Damaged or crushed fins restrict airflow, diminishing cooling performance. Visual inspection is key; look for bent, flattened, or broken fins. A constant ticking sound from the fridge can indicate ice buildup exacerbated by fin damage.

Straightening fins with a fin comb restores airflow. Severely damaged fins may require coil replacement. Maintaining fin integrity is vital for consistent temperature control and preventing excessive compressor strain, ultimately extending the unit’s lifespan.

Defrost System Troubleshooting

True freezers utilize temperature-terminated defrost systems, crucial for preventing ice buildup on evaporator coils. Troubleshooting involves verifying proper operation of heaters, timers (like the Grasslin Defrost Timer in freezer units), and sensors. Incorrect controller settings or bad sensors can cause frequent defrost cycles or insufficient defrosting.

Ice buildup leads to reduced cooling and potential compressor issues. A malfunctioning defrost system requires careful diagnosis, potentially involving component testing and calibration to restore optimal performance and temperature stability.

Understanding Temperature-Terminated Defrost Systems

True Manufacturing employs temperature-terminated defrost systems, differing from time-clock systems. These systems initiate defrost cycles based on evaporator coil temperature, not a pre-set time. Sensors monitor coil temperature, activating heaters when frost accumulates.

This method optimizes energy efficiency by defrosting only when needed. Proper function relies on accurate sensors and a functioning controller. Understanding this system is vital for diagnosing defrost-related issues, ensuring consistent cooling and preventing ice buildup within the refrigeration unit.

Grasslin Defrost Timer (Freezer Units) – Operation & Checks

True freezer units often utilize Grasslin defrost timers to manage defrost cycles. These timers mechanically control the defrost heater activation, transitioning between cooling and defrost modes. Checking the timer involves verifying proper rotation and contact point integrity.

A faulty timer can cause insufficient defrosting or excessive heater runtimes. Refer to the True Manufacturing documentation for specific timer settings and troubleshooting steps. Proper operation is crucial for preventing ice buildup and maintaining optimal freezer temperatures.

Sensor and Controller Problems

Temperature control relies heavily on accurate sensors and a functioning controller. Bad sensors can provide incorrect temperature readings, leading to erratic cooling or defrost cycles. Controllers, like the LAE model, manage these inputs and outputs, and failures can cause inconsistent performance.

Troubleshooting involves verifying sensor resistance values and controller settings. Incorrect calibration or a faulty controller can mimic other issues, such as low refrigerant. Always consult the True service manual for specific diagnostic procedures and replacement guidelines.

Identifying Bad Sensors

Faulty temperature sensors are a frequent cause of control issues in True refrigerators. Symptoms include wildly fluctuating temperatures or a failure to maintain the setpoint. Testing requires a multimeter to measure resistance; values outside the manufacturer’s specifications indicate a bad sensor.

Check sensor wiring for damage or corrosion. Consider the sensor’s location and potential exposure to moisture or physical impact. Replacing a suspect sensor is often the quickest diagnostic step, but verify the new sensor’s calibration post-installation.

Controller Settings and Calibration

Proper controller settings are crucial for accurate temperature management in True refrigerators. Incorrect settings, or a lack of calibration, can lead to inconsistent cooling. Refer to the manufacturer’s documentation for the correct parameters for your specific model.

Calibration may involve adjusting the temperature offset to match a known accurate thermometer. Incorrect calibration can cause the unit to run excessively or fail to cool adequately. If issues persist, contacting a qualified technician is recommended.

Refrigerant Issues & Temperature Control

Refrigerant levels directly impact a True refrigerator’s ability to maintain consistent temperatures. Low refrigerant, indicated by warmer temperatures and longer run times, requires professional attention. A clogged capillary tube restricts refrigerant flow, mimicking low refrigerant symptoms and hindering cooling performance.

Identifying these issues necessitates specialized tools and knowledge. Attempting to recharge refrigerant without proper certification is illegal and dangerous. Always consult a qualified technician for refrigerant-related concerns to ensure safe and effective repairs.

Low Refrigerant: Symptoms and Implications

Low refrigerant in a True refrigerator manifests as inconsistent cooling, extended compressor run times, and a gradual increase in cabinet temperature. Ice buildup, surprisingly, can also occur due to the evaporator coil becoming too cold. These symptoms indicate a leak in the sealed system.

Ignoring low refrigerant leads to compressor failure, costly repairs, and potential food spoilage; Refrigerant handling requires EPA certification; attempting DIY repairs is illegal and environmentally damaging. Professional leak detection and repair are crucial for optimal performance.

Clogged Capillary Tube – Impact on Cooling

A clogged capillary tube severely restricts refrigerant flow, hindering the cooling process within a True refrigerator. This restriction causes high-side pressure to drop and low-side pressure to rise, leading to inefficient cooling and potential compressor damage. Ice formation near the capillary tube is a common indicator.

Symptoms include warmer cabinet temperatures, longer compressor cycles, and potentially, a complete cooling failure. Addressing a clogged tube requires a qualified technician to evacuate, flush, and recharge the system. Preventative maintenance is key to avoid this issue.

Troubleshooting Specific True Models (T49 Example)

The True T49 model frequently exhibits issues with evaporator coil icing and damaged condenser fins, impacting temperature control. Inspect the coils for obstructions and ensure proper airflow. A common problem involves the Grasslin defrost timer, requiring verification of correct operation.

Check for bad sensors and controller settings, as these can cause inconsistent cooling. Low refrigerant levels are also a potential cause, necessitating a leak check and recharge by a qualified technician. Regular fin straightening is crucial for optimal performance.

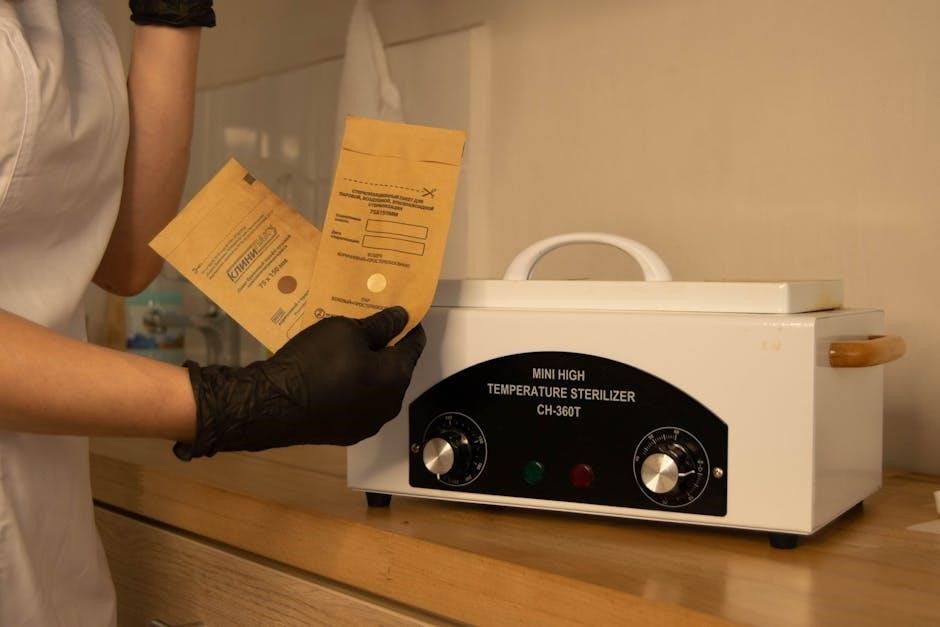

Safety Information & Precautions

Always disconnect power before servicing any True refrigeration unit to prevent electrical shock. Refrigerant handling requires EPA certification; improper handling poses environmental and health risks. Wear appropriate personal protective equipment, including gloves and eye protection.

Exercise caution when working with sharp edges on coils and components. Never bypass safety controls or modify wiring. If unsure about any procedure, consult a qualified refrigeration technician. True Manufacturing advises against altering electronic controls.

Temperature Control Adjustment Procedures

Initial temperature settings should align with recommended food storage guidelines. For precise adjustments, consult True Manufacturing directly or a qualified refrigeration technician. Avoid drastic changes; incremental adjustments are preferred for stability.

Monitor temperatures with a calibrated thermometer after each adjustment. Consider shelving and lighting impacts on temperature distribution. If using a LAE controller, verify settings are correct. Reddit users suggest professional assistance for newer True freezers.

When to Contact a Professional Technician

If temperature fluctuations persist despite adjustments, or if you suspect refrigerant issues like a clogged capillary tube, a technician is crucial. Complex defrost system problems, particularly with temperature-terminated systems, require expert diagnosis.

Don’t attempt repairs involving electrical components without proper training. Issues with Grasslin defrost timers or controller calibration necessitate professional intervention. When in doubt, prioritize safety and contact True Manufacturing or a certified refrigeration technician for assistance.

True Manufacturing Resources & Support

True Manufacturing’s official website, www.truemfg.com, provides extensive documentation, including detailed parts lists and troubleshooting guides. For specific model support, like the T49, utilize their online resources or contact their customer service directly.

Local refrigeration technicians certified to work on True equipment are also valuable resources. PartsFPS offers replacement components, such as condenser coils, streamlining repairs. Remember to consult the official manual for safety information and proper procedures before undertaking any maintenance.

Shelving, Lighting & Their Impact on Temperature

Proper shelving installation and organization are crucial for maintaining consistent temperatures within True refrigerators. Overcrowding restricts airflow, leading to inconsistent cooling. Similarly, the placement of lighting can introduce localized heat.

Ensure shelving allows for adequate air circulation, and consider the heat output of lighting when arranging products. Refer to the True Manufacturing manual for specific shelving installation guidelines and light switch operation instructions. Optimizing these elements contributes to overall temperature stability.

Field Troubleshooting Guide (Freezer Units)

This guide provides on-site troubleshooting steps for True freezer units, focusing on common issues affecting temperature control. Begin by verifying power supply and connections, then inspect evaporator and condenser coils for ice buildup or damage.

Pay close attention to the Grasslin defrost timer’s operation, and assess sensor functionality. Consult the True Manufacturing manual for detailed diagrams and specific model instructions. Remember to prioritize safety and, when in doubt, contact a qualified technician.